When school is out, manufacturer ramps up locker production with rolling pinchers that cut down reliance on shearing

When school is out, manufacturer ramps up locker production with rolling pinchers that cut down reliance on shearing

December 2015 - Summer, which we wish it still were, is a busy time of year for List Industries Inc. That’s because the Deerfield Beach, Florida-based manufacturer serves the education market, manufacturing lockers for high school and junior high gym students across the country.

“When the schools are closed, that’s when everyone wants their new lockers and we’re at our busiest,” says Rich Machesney, manufacturing manager at List Industries.

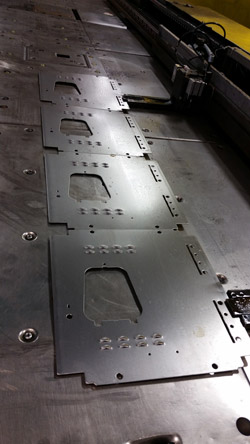

One locker design that is particularly popular includes an 18-degree slope at the top. This feature ensures the students are not able to place their books on top, and then forget them in gym class.

Manufacturing the sloped part required the use of a shear, which increased production time. The part started at the turret press, then went to the shear, then was finished at the press brake.

“It was an inefficient process to send the part across the room to the shear,” Machesney says. “Not to mention it made for questionable accuracy.”

Because of the shear requirements, the shear operator had to feel the dimples of the part hitting the blade and then hit the pedal strip on the press brake without seeing if it was lined up correctly. With this setup, Machesney indicated there was definitely a chance for operator error.

To tighten up efficiencies, Machesney visited with Wilson Tool, White Bear Lake, Minnesota, about new turret presses and learned about the available rolling pinchers. Part of the Wilson Wheel family of products and available on the turret presses, the rolling pinchers allowed List Industries to completely eliminate shearing for manufacturing this particular part.

To tighten up efficiencies, Machesney visited with Wilson Tool, White Bear Lake, Minnesota, about new turret presses and learned about the available rolling pinchers. Part of the Wilson Wheel family of products and available on the turret presses, the rolling pinchers allowed List Industries to completely eliminate shearing for manufacturing this particular part.

The main feature of the rolling pincher tool thins the edge of the part by pinching a line along the sheet metal. This action creates a thinner part-dimension line, making the part easier to break apart after it is removed from the turret machine. The thin line created by the pinching process is akin to a perforation on a piece of paper, which gives operators cleaner part edges and fewer steps in the process.

“With the rolling pincher we are able to punch the panel, break off the angled scrap, and pass the part to the press brake to be completed and put in a gondola, all in the same work cell,” Machesney says “That’s how we could eliminate the shearing step, which saved a lot of time and labor.”

As well as increasing part production efficiencies, the rolling pinchers on the turret presses additionally helped List Industries eliminate waste.

“We bring in our steel in coils slit to sizes of the turret press blank and are able to ‘break’ a multiple part blank and eliminate that re-shearing operation as well,” Machesney says. “We also get the accuracy beyond what a shear operator might deliver and there’s very little waste.”

Combining greater production efficiencies and reduced waste, List Industries is enjoying the added benefits that come with using rolling pinchers on the turret presses.

“We’ve learned that we could press brake a multiple punched blank and then ‘break’ them apart for more time saving” Machesney says. “We have the rolling pinchers in all four of our turrets and they get used every day.”

With the implementation of the new turret presses with rolling pinchers, List Industries determined their operations were heavy on shearing equipment, so shipped one off to a different location within the company.

“We found we didn’t need a shear,” Machesney says. “We eliminated it because we just didn’t need it. With the efficiencies on handling, production and manufacturing multiple parts at once, using the rolling pinchers is a new way of life for us.” FFJ