Mazak Optonics Corp.

Elgin, Illinois

847.252.4500

847.252.4599

www.mazakoptonics.com

Mazak on Social Media:

|

|

| See more from Mazak Optonics Corp. on FFJournal.net > |

Mazak Optonics Corp. is a major supplier of laser-cutting systems, offering 50 laser models and leading the industry in the implementation of emerging laser technologies. The company’s 50,000 sq. ft. North American Headquarters are located in Elgin, Illinois, and feature a 30,000 sq. ft. laser technology center housing up to 18 machines for demonstrations and training. Mazak Optonics is part of Yamazaki Mazak Corporation (Oguchi, Japan), the global leader for the manufacture of machine tools and systems for the precision machining of metal parts, including CNC turning centers, horizontal and vertical machining centers, Multi-Tasking machining centers, turnkey cells and software solutions. The North American Headquarters for Yamazaki Mazak are located in Florence, Kentucky. For more information on Mazak Optonics’ products and solutions, visit www.mazakoptonics.com, email

Featured Product: THE NEXT GENERATION OF HIGH-POWER CUTTING MACHINES WITH MAXIMUM CONTROL

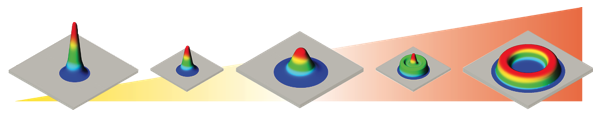

The NEW Mazak OPTIPLEX 3015 NEO 15kW is a 2D fiber laser-cutting system equipped with technology that allows increased control of beam shape and beam diameter. Featuring state-of-the-art Variable Beam fiber laser technology, NEO achieves high speed and high-quality cutting. The result is optimal laser-cutting performance in a wide range of materials.

Large front and side access doors offer full-width and full-length opening. Minimized work area restrictions make it easier for operators to load material onto the machine and unload finished parts.

The new MAZATROL SmoothLx CNC control features a large 21.5” screen and touch panel. Dual monitors allow multiple applications to run simultaneously. Additionally, the CNC control rotates giving operators the flexibility to work at the front or side of the machine.

Mazak’s OPTIPLEX 3015 NEO is equipped with numerous Intelligent Functions—including Nozzle Changer, Nozzle Centering Camera, and Camera Assisted Part Nesting. The Intelligent Machine functions utilize innovative technology to support operators and ensure maximum machine performance.

PERFORMANCE ADVANTAGES

- Beam shaping technology delivers optimal thick and thin metal cutting, higher cutting speed, superior edge quality, and improved piercing time.

- Large front and side access doors minimize restrictions when loading/unloading material.

- New MAZATROL SmoothLx control features a widescreen and touch panel for ease of operation.