Supplier helps manufacturers beat the pressure cooker created by short lead times and shorter delivery schedules

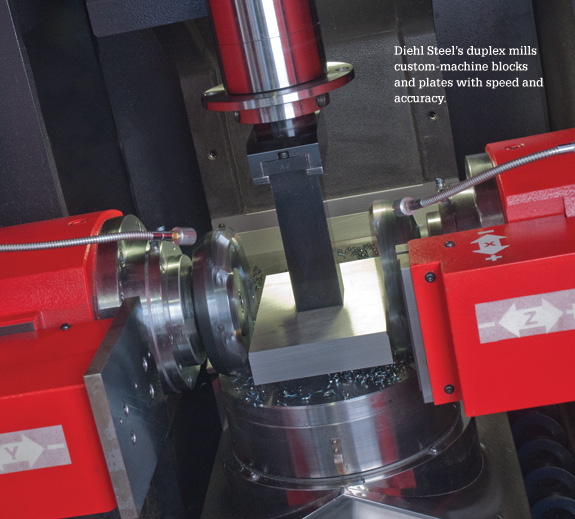

Above: Accu-Square material is custom machined to customers’ specifications.

Supplier helps manufacturers beat the pressure cooker created by short lead times and shorter delivery schedules

November 2015 - Sailors once used a crow’s nest, a barrel or platform fastened to a ship’s mainmast as a lookout to spot potential hazards, other vessels and land. Perched upstream from its supply chain, Diehl Steel is likewise equipped to monitor customer needs and changing market conditions. This vantage point allows the Cincinnati, Ohio-based supplier of tool steel, alloy steel, powder metal products and mold steel to anticipate problem areas and implement solutions. In the last few years, these hurdles have included helping manufacturers confront dwindling lead times and delivery schedules while circumventing fallout from the lack of skilled workers and the influx of cheap steel imports.

The search for solutions sometimes leads Diehl Steel outside its comfort zone. At the same time, the raw materials supplier sees plenty of opportunity.

A poll of National Tooling & Machining Association member companies found 78 percent have at least one job opening and more than 30 percent have at least two open positions. “Shop floor technology has evolved creating a need for ‘bluetech’ workers who understand the mechanics of these advances and how to problem solve,” commented NTMA President Dave Tilstone.

Industry-fostered education and training programs for entry-level applicants are being established to address the problem.

Growing pains

“It’s a great time for young people to get excited about manufacturing,” says Jim Brackman, vice-president of marketing for Diehl Steel. “NTMA’s 2014 Wage and Benefits Survey reported an hourly rate of $25 for an experienced machinist. Reshoring of high precision, value-added parts also continues to gain momentum—creating additional opportunities.”

According to the Institute for Supply Management, manufacturing activity expanded in September for the 33rd consecutive month (albeit at a slower rate than during most of the first half). Fabricated metal products was one of nine industries that reported production growth.

Diehl Steel, in business nearly 90 years, inventories tool steel and alloy steel flats, squares and blocks for makers of special dies and tools, jigs, fixtures and industrial molds; and industrial and commercial machinery and equipment. These customers in turn supply industries as varied as automotive, appliance, medical, power generation and aerospace. The agile company built its reputation on the ability to provide these products at full throttle for progressive die applications.

“Our customers are dealing with nearly impossible lead times and schedules,” Brackman says. “If they quote 12 weeks for a job, their customer invariably responds with a requirement for eight to 10 weeks. These demands—coupled with challenges like labor shortages—put our customers under tremendous pressure.”

Diehl Steel helps toolmakers cope in several ways. Preprocessing frees toolmakers from elementary shop tasks and allows them to focus on complex detail work, a step that compensates for a lack of man hours while saving time and resources.

“Over the last two years we’ve invested more than $2 million in our Accu-Square technology, which supports our core strategy to deliver saw cut-to-size or premachined, six-sided square material quickly and reliably,” says Mike Sheehan, president of Diehl Steel.

Accu-Square can premachine tool, alloy, high-speed, stainless or carbon steel into finished flats, squares or parallel to a toolmaker’s specified tolerances. Diehl also uses the technology on powdered metal products.

Diehl Express service gets product to a customer’s dock the next day if the order is placed by noon EST. “With Accu-Square we can cut and square material and ship it the same day at no additional cost,” Sheehan says. “The service is designed to support up to 10-piece quantities.

The service center has also built up an inventory of popular grades and precut sizes, making the majority of purchase orders candidates for the Express service. “It allows us to be a local resource to most any customer in the country,” Sheehan says, adding, “We often hear from customers who say, ‘You saved us a week in processing.’”

Diehl Steel also sees requests rising for powdered-metal tool and die steels that provide extremely high wear resistance in combination with high impact toughness. Powder metallurgy typically blends and heats fine powdered materials and compacts them in a controlled atmosphere to bond and solidify the metals.

“It’s become a significant percentage of our business,” says Sheehan. “If someone is building a die with conventional D2 products they might see production in the range of 500,000 parts. A powder metal coated die can easily produce three to four times the number of parts before it needs to be resharpened.”

While Diehl produces rounds for a small market segment, the supplier remains focused on cold work steel flats, which comprise about 80 percent of its business. Rounds are fairly simple to cut and generally used in mass-produced goods.

Staying on top

“Our growth will continue to focus on flats,” Sheehan emphasizes. More difficult to cut, flats also generate more scrap, which makes yield calculations, pricing and quoting critical to the company’s profit margin.

“We’re cutting one-offs in unique sizes so it’s challenging to find software capable of optimizing cutting parameters for us,” he explains. But Diehl has developed its own methodology which gang cuts material while controlling scrap and ensuring efficient use of plate. “It’s a good fit for our fast service and delivery goals,” Sheehan notes. “We can cut, machine and provide six-sided squares that are ready to go once they reach a customer’s job shop.”

Diehl Steel uses proprietary material sourcing and screening techniques that include various tests on samples sent to an independent metallurgy laboratory. Small samples are field tested, followed by a lengthy trial period to ensure the material meets customer specifications.

He notes that in more than 30 years in business, he does not recall any time when “dumping of cheap, low-quality steel was so prevalent” as now. “That’s why we only source from mills with the highest industry reputation for quality steel. We have to be vigilant because if we were to get poor-grade steel it would be evident right away versus steel supplied for a structure like a bridge where it might take decades before quality issues surface.” It may take six to 12 months to qualify a new mill source.

In addition to monitoring its material, Diehl Steel saw cuts, centerless grinds, mills, machines and makes hollow bar and tool steel EDM blanks. Electroslag-remelting materials offer cleanliness with minimal nonmetallic inclusions. Mold quality materials—suited to applications requiring clean, uniform products—can be polished to a high finish. The supplier is also a source for material that meets North America Die Casting Association [NADCA] specifications.

While Diehl Steel will remain a go-to resource for cold work flat products, Sheehan is exploring the possibility of adding hot work steel products to the company’s growing inventory. FFJ