Fabricator reduces number of complex bending setups with staged tooling

Fabricator reduces number of complex bending setups with staged tooling

June 2017 - Most job shops run into lead-time challenges when facing tough customer demands. But cranking out high quality, complex parts under stringent deadlines isn’t always an easy task. When DeWys Manufacturing invested in new press brakes several years ago, the production team discussed various challenges in the shop and how new technology could help reduce setups, decrease part handling and limit downstream operations while producing high quality, complex parts.

Based in western Michigan near Grand Rapids, DeWys researched different tooling options for the new brakes. After learning about the types of tooling manufacturers were offering, the fabricator selected a variety, and among them were multiple sets of staged bending tools.

“When we were upgrading our press brakes we looked at the different options of compatible tooling,” said Chris Hawkins, operations manager at DeWys. “The versatility of staged tooling gave us the ability to use varying tool types in the press brake simultaneously. Our operators previously had to set jobs up multiple times just to complete a part run. The numerous options with staged tooling made us lean toward making that investment.”

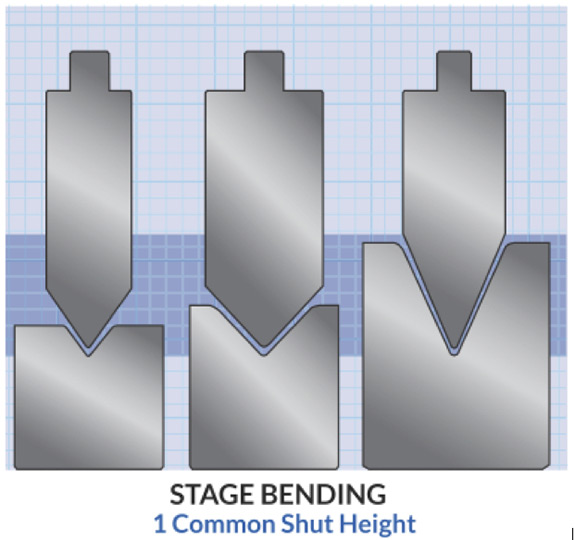

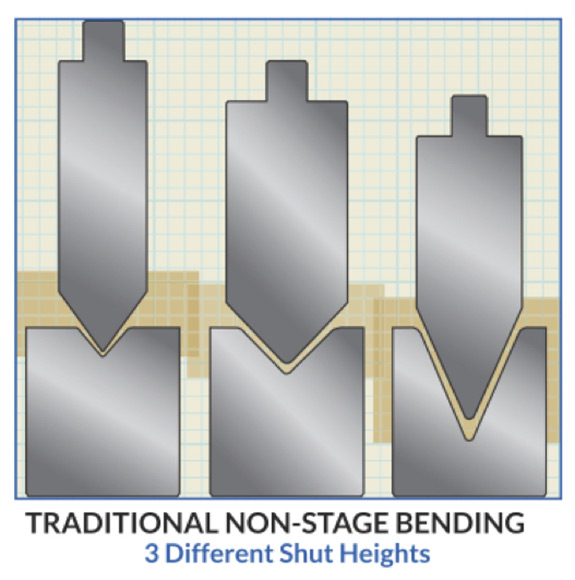

Stage bending is a common practice when operators face a complex part design that requires contrasting tool profiles. The challenge encountered with these bending scenarios is the varying tool profiles cannot close at the same height in the brake. As a result, the taller profiles collide and the shorter profiles do not engage. Staged tooling allows the different tool profiles to exhibit the same closed height, which allows the operator to perform the entire bend sequence with one setup.

“Before we invested in our new press brakes, we made a lot of shims and custom extensions to achieve the common shut-height, which added a great deal of time to complete changeovers,” Hawkins said. “Most jobs required about two or three setups and shims or extensions for just about every tool set in the job.”

As well as the time involved shimming tools and setting up jobs on the press brake, operators at DeWys spent significant time double- or triple-handling the material through the process, often coming back to the beginning to re-bend or scrap a finished part that didn’t meet design or quality requirements.

“Handling the material multiple times was a huge disadvantage that went away when we implemented staged tooling,” Hawkins said. “We also improved the rate at which we completed a good part at the end of a run. At times we looked at a finished part run and realize we needed to add or subtract a little out of a particular bend. We’d be past the point of making corrections, so we’d have to scrap the run and start over.”

Reducing the amount of setups and material handling with staged bending tools helped DeWys not only improve production and part flow, but gave the company competitive advantages when bidding on new projects.

“We are definitely more competitive with new bids by being able to handle complex jobs that require multiple tool sets and different setups,” Hawkins said. “Instead of setting up a job three times and handling the sheet three times, we can set it up once and handle it once. That means we can get the part to our customer in a shorter window of time compared to shops that are still stage bending with shims.”

Even with the most confounding complex jobs, DeWys is still able to use stage bending to increase efficiencies by reducing setups, material handling and downstream operations.

“We have a lot of jobs that call for smaller V dies and larger radius punches all in the same setup. The flexibility of using multiple radiuses in staged tooling is definitely beneficial,” Hawkins said. “We can order a specialty tool that is job-specific and have that staged to run right with our regular tooling as well as a specialty offset tool. Being able to run all of these tool sets at the same time is a real time saver.”

Saving time, increasing efficiencies and reducing lead-time all while maintaining part quality are some of the greatest benefits DeWys has experienced by investing in staged tooling. Cost savings come into play as well, which is an additional benefit DeWys can pass on to customers. And while Hawkins hasn’t crunched the numbers, he’s confident the savings are there.

“We don’t really have a number for cost savings,” he said. “But it goes without saying that if we’re not performing multiple setups, and we’re not double-handling our parts from one operation to the other, we’re saving money.”

[h/t Wilson Tool]